RESTORATION AT CHEZ L'HORLOGER

Maintenance, cleaning and restoration at Blonay

Discover all the steps involved in the restoration of a clock or watch

When l'Horloger talks about restoring your clock or watch, he is not just thinking about cleaning it or oiling the movement. Restoration involves several stages.

So what does restoration involve?

Restoration of a clock is not simply a matter of cleaning or a fresh application of oil. It involves careful work that consists of repairing all worn parts, if necessary remaking those that no longer work or are missing, cleaning or taking the rust off each train, and so allowing the piece to operate like new.

What should you do to restore your clock?

Because of the lifespan of the oils used, a clock should be overhauled every five to ten years. But that depends on where the customer positions the piece at home, variations in temperature and the proximity of sources of heat (radiator, chimney, television). Clocks can work for longer but in that case they will turn with the oils dried out and polluted with dust. This combination produces an abrasive and the clock runs abnormally, resulting in it working poorly and finally stopping completely.

As far as watches are concerned, plan on an overhaul every two to five years.

Don't hesitate to ask the advice of your qualified clock and watchmaker. Restoring your clock or watch will be carried out according to regulations and will be accompanied by a guarantee.

Visualisation

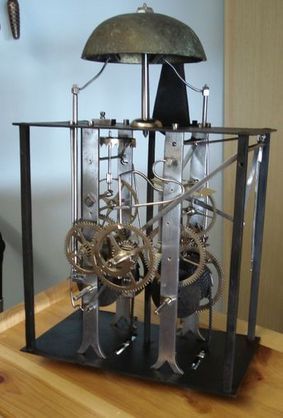

Before dismantling a clock or watch, it is advisable for l'Horloger to study the working of the piece and to carry out certain checks which can provide him with an indication of the causes for its not working properly. Evaluation of the movements, striking mechanism, escapement, etc.

Disassembly

Next you have to dismantle and separate the movement from its case, lift out the dial and the hands, undo the barrel springs and completely dismantle the movement. All the items are placed in order on the work surface.

Cleaning

All the items that make up the movement are grouped by function and dipped for several minutes in a range of baths which remove grease, deoxidise, clean and rinse. We also clean the holes in the bearings with wooden pegs.

Polishing

All the items are brushed and polished on a range of buffing wheels which means that the wheels and plates are clean, free of rust and shining, just the finish you want.

Bushing

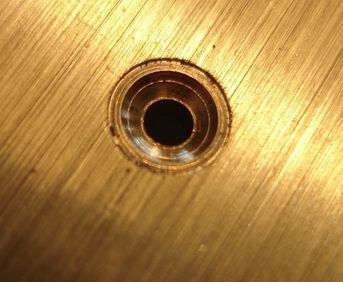

All the wheels, one after the other, are arranged on the plates, in their correct holes. L'Horloger checks if there are signs of wear and if the interior of the bearings is out of round.

When a fault is apparent, you must bush it, which consists of piercing a hole of a wider diameter where the out of round bearing is located and inserting a bush whose new bearing corresponds to the diameter of the corresponding pivot.

All the other worn pieces must be put right or if necessary remade and replaced. You must recheck the movement of each wheel as well as each gear to avoid any risk of the timepiece stopping.

Pivoting

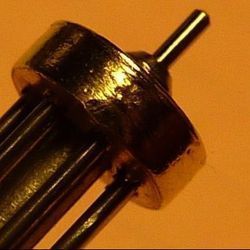

After several years' use, a clock can often be left with scratched or worn pivots. These must be polished so that they can turn in their bearings without any resistance.

If the pivot is too small in diameter or is broken, a new pivot will need to be fitted. This consists of boring the wheel arbor on the site of the damaged pivot and insert an arbor which will become, once it has been shaped, a new pivot.

Repairing the spindle of a barrel

The barrel arbor spindle often becomes misshapen or warped from using a key that is too large or worn. This softens the angles of the spindle and makes large burrs, which makes it impossible to wind up the clock.

By hammering, shaping and polishing, l'Horloger will refashion a new spindle and will provide a new key that will be a perfect fit.

Remaking the eye of a barrel spring

Over the years and having undergone a lot of stress, the eye of a spring can become damaged. The spring has to be softened over several centimetres and the defective part removed.

After a new hole has been bored, its contours have to be shaped to restore the desired shape to the eye.

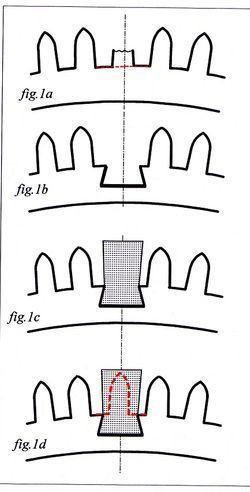

Replacing a broken tooth

One important repair has to do with replacing a broken or bent tooth. You have to remove the remains of the broken tooth and make a dovetail notch.

Then, using a brass plate, you have to cut out a strip that fits in the notch and solder it on.

Finally, you have to shape the strip to obtain a tooth which is the same shape as the others. A last bit of polishing and the repair is finished.

Repairing the lever

The lever or escapement is the train that is required to communicate to the balance the driving force necessary for the maintenance of its oscillations. This piece is very important and requires the greatest care to ensure the good working order of the clock or watch.

After years of use, the lever's pallets are often worn or marked by the passage of the teeth of the lever wheel. So these need repairing by shaping them and polishing them so that they get back to optimum working order.

Oiling

Lubrication of a clock or watch is usually done by adding a drop of oil or grease in the bearing oil sinks and on all the workings which exert any kind of friction.

General checking

Once the whole movement is reassembled, each working part and movement is checked, regulated and if necessary modified.

Cleaning clock cases and polishing watch cases

Depending on the piece, wooden clock cases are cleaned and waxed while watch cases are polished. If necessary, some of the paintwork will need touching up or the decoration re-covering with gold leaf.

Finishing touches

Dials and hands can also be fixed. Enamel dials often need to be restored or refreshed because they can get cracked, chipped or oxidised. Once the movement is finished, it is put back in its case or housing. Sometimes l'Horloger calls on specialist craftsmen (cabinetmakers, workers in enamel, bronze or gold) so that your clock is restored to its original state.

Final check

Over several more days, the clock or watch is wound up, regulated and carefully checked for accuracy and guaranteeing that it is in good working order.